Machine vision can inspect the tiniest objects, which presents a huge advantage over manual inspections. An example is the needle tip inspection system developed by ADD Innovations for one of the largest medical equipment manufacturers in India.

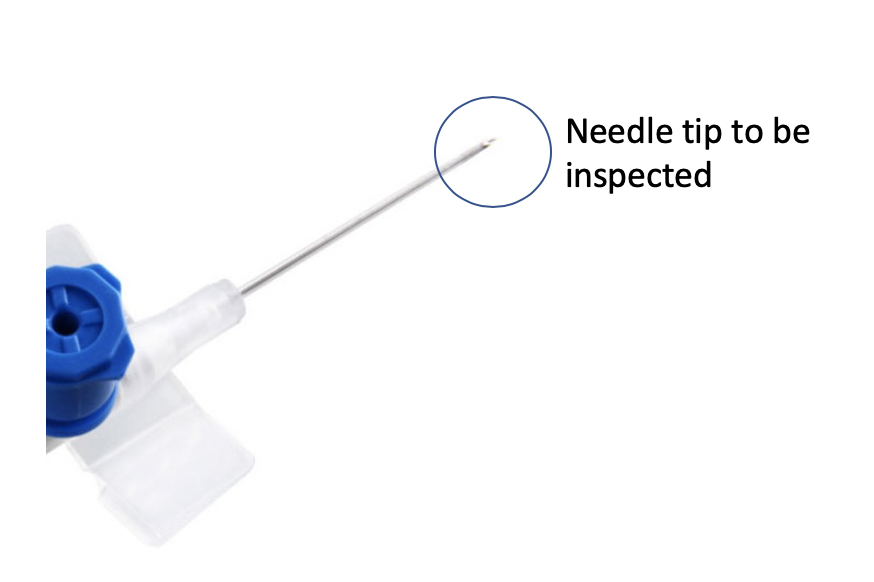

Inspecting the needle tip size and sharpness is critical in healthcare applications – especially where the needle is attached to an invasive device. Poorly inspected specimens can lead to patient discomfort, complications, or even severe negative health indications.

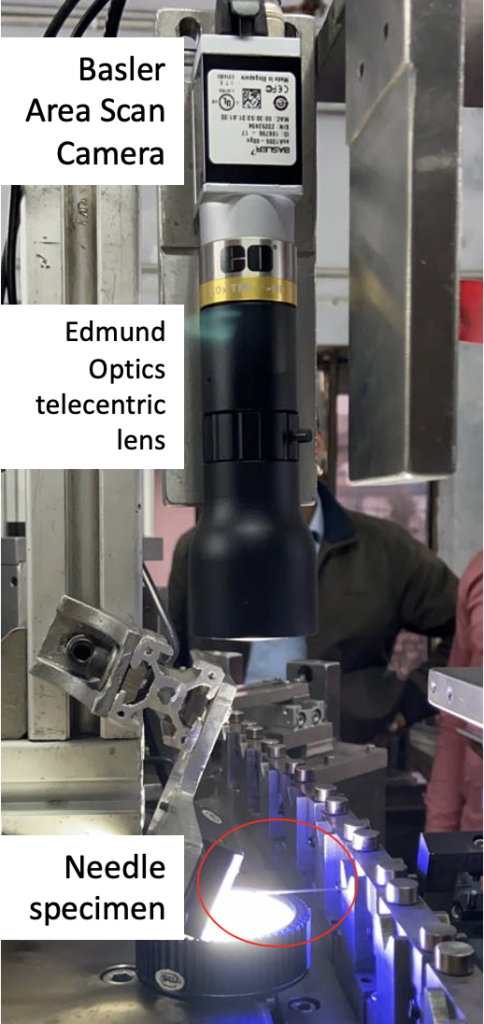

The machine vision system developed by Add Innovations packages industrial grade area scan cameras by Basler AG, with telecentric lenses from Edmond Optics with a processing time of only 1 milli second.

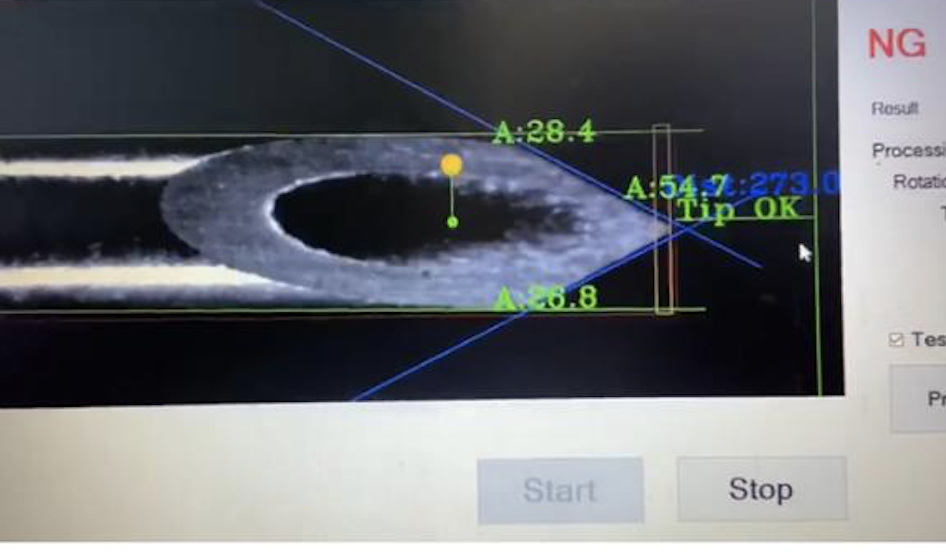

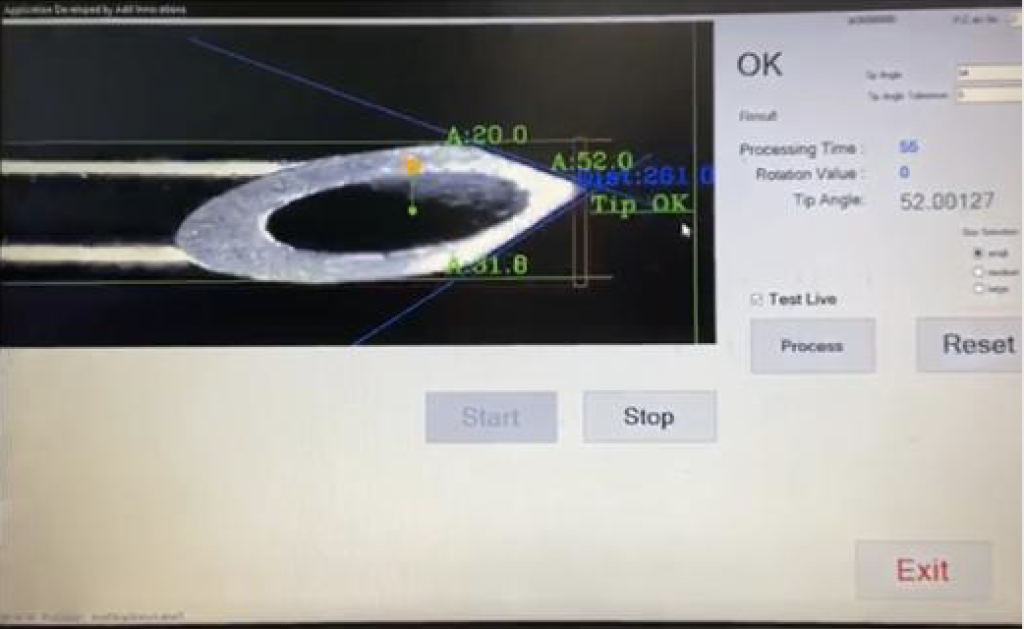

The hardware is paired with Add Innovations, proprietary machine vision software. The system checks for needle orientation, slant needle, and blunt tip in a fraction of a second and sorts specimen into “OK” and “no good” classes.

The following video shows the software UI in action in real time.