In the automotive manufacturing industry, ensuring the highest standards of quality is crucial, especially when it comes to safety-critical components like windshields. Windshields not only protect the driver and passengers but also play a vital role in the proper functioning of sensors, cameras, and other technologies embedded in modern vehicles. One critical aspect of windshield production is the print inspection of logos, markings, and other printed elements on the glass. The print inspection system for automotive windshields, powered by machine vision, is designed to ensure that these prints meet strict quality standards, are applied accurately, and are free from defects.

In this article, we will explore the importance of print inspection in automotive windshield production, how machine vision systems enhance this process, and the benefits they bring to manufacturers.

The Importance of Print Inspection on Automotive Windshields

Automotive windshields often have various printed elements such as:

- Manufacturer logos

- Safety markings (e.g., DOT numbers)

- Certification marks

- Tint patterns

- Labels for features such as heating elements, sensors, or antennas

These prints not only convey important information but also must adhere to regulatory standards for safety and certification. Errors or defects in these printed elements can lead to safety concerns, legal issues, and poor customer satisfaction. Inconsistent printing, smudges, misalignment, incorrect information, or faded prints could compromise the windshield’s integrity and functionality, especially in high-performance vehicles or advanced safety systems that rely on clear visibility and accurate sensor calibration.

For example, incorrect logo placement or illegible safety markings could lead to non-compliance with industry regulations, making it necessary for manufacturers to detect and correct these issues before the product leaves the factory.

Machine Vision for Print Inspection on Windshields

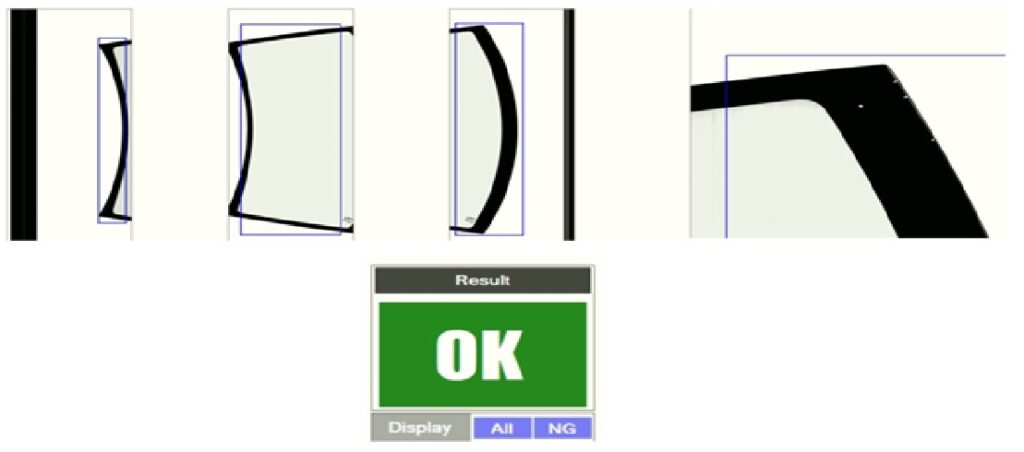

Machine vision technology provides a powerful solution for automating the inspection of prints on automotive windshields. Machine vision systems rely on high-resolution cameras, specialized lighting, and advanced software algorithms to capture, analyze, and evaluate images of the windshield’s surface to detect and verify printed marks and labels. These systems can detect a wide range of defects and ensure that the print quality adheres to predefined standards.

Here’s how machine vision works in the print inspection process for automotive windshields:

1. High-Resolution Imaging

The first step in the print inspection process is capturing a high-resolution image of the printed area. High-definition cameras are used to scan the surface of the windshield at multiple angles and lighting conditions. This ensures that every detail of the print, including any micro-defects, is visible for inspection.

Depending on the windshield’s design and the type of print, multiple cameras or a combination of cameras may be used to inspect both the printed and non-printed areas of the glass.

2. Image Processing and Analysis

Once the image is captured, advanced image processing algorithms analyze the visual data for a range of characteristics, including:

- Print location: Ensuring logos and markings are correctly positioned.

- Print quality: Identifying defects such as smudges, fading, misalignment, or inconsistent ink distribution.

- Print clarity: Verifying that the print is legible and not distorted due to manufacturing defects.

- Correctness of the print content: Ensuring that the printed marks meet the required standards, such as certification codes and safety labels.

Machine vision systems use pattern recognition and optical character recognition (OCR) to validate the printed text, ensuring that it matches the required specifications. By comparing the captured image with a reference image or database, the system can quickly flag any discrepancies.

3. Real-Time Detection and Feedback

One of the significant benefits of using machine vision in print inspection is the ability to detect defects in real-time. If a print defect is found, the system can immediately flag it, stop the production line, or even trigger corrective actions such as removing the defective windshield from the line for rework. Real-time feedback ensures that defects are caught early, reducing the risk of defective products reaching customers.

4. Automated Sorting and Sorting System Integration

Once defects are identified, machine vision systems can automatically sort out windshields that fail the inspection. The system can be integrated with other automated systems to remove faulty products from the production line and replace them with properly printed windshields. This minimizes the need for manual inspection, saving both time and labor costs while ensuring consistency.

Benefits of Machine Vision for Print Inspection in Automotive Windshields

1. Improved Print Accuracy and Consistency

Machine vision ensures that each print is applied consistently, meeting the manufacturer’s quality standards. Whether it’s a logo or safety marking, machine vision guarantees that the printed elements are accurately placed and visible, avoiding errors that could lead to non-compliance with industry regulations.

2. Reduced Human Error

Traditional manual inspection can be prone to errors due to fatigue or inconsistencies in human judgment. Machine vision systems eliminate the subjectivity involved in manual inspections by relying on precise algorithms to detect defects, leading to more reliable and consistent results.

3. Increased Inspection Speed

Machine vision systems can process and inspect windshields much faster than human operators, which is crucial in high-volume manufacturing environments. Faster inspections mean less downtime on production lines and a quicker turnaround time for each product.

4. Cost Savings

By automating the print inspection process, manufacturers can save on labor costs and reduce the number of defective windshields that need to be reworked or replaced. Early detection of print defects helps minimize waste and costly product recalls. Additionally, reducing the reliance on manual inspections leads to a more efficient workflow and higher throughput.

5. Enhanced Product Quality

Consistently inspecting prints ensures that windshields meet high-quality standards, which contributes to the overall quality of the vehicle. Whether for aesthetic purposes or safety-related features, high-quality printed elements ensure the windshield’s functionality and appearance meet customer expectations.

6. Compliance with Industry Regulations

Automotive windshields must meet specific safety and regulatory standards, and machine vision systems ensure that the required markings are printed correctly. This includes verifying regulatory certifications, country-specific markings, and safety features that could impact vehicle compliance with government regulations.

Applications of Print Inspection Systems for Automotive Windshields

Machine vision-based print inspection systems are particularly valuable for several key applications in the automotive industry:

1. Logo and Branding Verification

Machine vision systems ensure that logos and branding on automotive windshields are applied correctly and consistently. Whether it’s the manufacturer’s logo, the model number, or the vehicle’s country of origin, these prints must be accurate and aligned properly for legal and branding purposes.

2. Safety Markings and Certification

Safety markings, including the DOT (Department of Transportation) code, windshield heating marks, and certification labels, are crucial for legal compliance. Machine vision ensures that these markings are printed clearly and correctly, maintaining compliance with safety standards.

3. Tint and Pattern Inspection

Windshields may have specific tinting or patterning printed to reduce glare, enhance comfort, or support advanced driver-assistance systems (ADAS). Machine vision systems can inspect these features to ensure the pattern is uniform and aligned as per design specifications.

Conclusion

As the automotive industry continues to evolve, the demand for high-quality, defect-free components becomes increasingly important. The print inspection system for automotive windshields using machine vision plays a pivotal role in ensuring that the printed markings and logos meet stringent quality and safety standards. By automating the print inspection process, manufacturers can improve efficiency, reduce errors, and ensure compliance with industry regulations.

Machine vision provides manufacturers with the tools needed to stay competitive, reduce costs, and improve product quality, making it an essential part of modern automotive production. With continued advancements in machine vision technology, the future of windshield production looks increasingly automated, accurate, and reliable.